Aim:

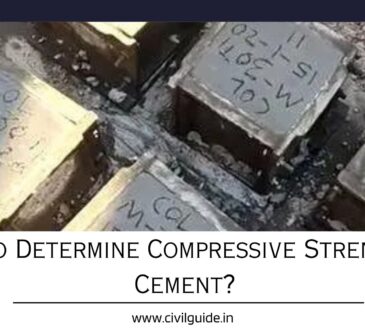

This lab activity aims to determine the compressive strength of cement.

Theory:

Compressive strength is one of the most important mechanical properties of cement that defines its ability to resist compressive stresses without undergoing any deformation or failure. The compressive strength of cement is defined as the maximum load it can bear without,

collapsing under compression. In the construction industry, compressive strength is a crucial factor as it directly influences the stability and durability of structures. The compressive strength of cement is commonly measured using a standardized testing method,

and the results are usually expressed in units of N/mm2 or MPa. This testing method is widely used to assess the quality and reliability of cement products used in various construction projects.

Apparatus and Materials Required:

The following apparatus and materials are required for performing the compressive strength test of cement:

- Tamping rod

- Compressive testing machine

- Balance

- Water

- Cement

Procedure:

The following steps should be followed to perform the compressive strength test of cement:

- Prepare a cement paste by mixing 400 g of cement with a measured quantity of water to achieve a standard consistency.

- Fill the cube molds with the cement paste in three layers and compact each layer using a tamping rod.

- Level the surface of the cement paste and keep the molds in a moist room for 24 hours.

- Remove the cube molds from the moist room and wipe off any excess water.

- Place the cube molds on the compression testing machine with the load-bearing surfaces facing upwards.

- Apply the load to the cube molds at a rate of 140 kg/cm2/min until failure occurs.

- Record the maximum load applied to the cube molds and calculate the compressive strength of the cement using the formula: Compressive strength = Maximum load / Cross-sectional area of cube mold.

Results:

The results of the compressive strength test of cement can be presented in the form of a table and graph. The table should include the following details:

- Sample ID

- The maximum load applied to the cube mold (kN)

- The cross-sectional area of the cube mold (mm2)

- Compressive strength of cement (N/mm2)

The graph should show the cement’s compressive strength versus the sample’s age. The graph helps in visualizing the change in the compressive strength of cement over time.

Precautions:

The following precautions should be taken during the compressive strength test of cement:

- The cube molds should be clean and dry before use to prevent any errors in the test results.

- The cement paste should be mixed thoroughly to achieve a standard consistency.

- The cube molds should be filled in three layers and each layer should be compacted using a tamping rod to avoid any voids in the cement paste.

- The cube molds should be kept in a moist room for 24 hours to ensure proper hydration of the cement.

- The compression testing machine should be calibrated before use to avoid any errors in the measurements.

- The load should be applied at a constant rate to obtain accurate and reliable results.

Conclusion:

In conclusion, the compressive strength of cement is an important property that determines its ability to withstand a load without breaking. The compressive strength test is a widely used method for determining the compressive strength of cement.

This lab activity provides students with hands-on experience in performing the compressive strength test of cement and helps them understand the importance of this property in the construction industry.

The results of this lab activity can be used to compare the compressive strength of different types of cement and to determine the quality of cement used in construction projects. By following the procedure and taking the necessary precautions, accurate and reliable results can be obtained.