Introduction

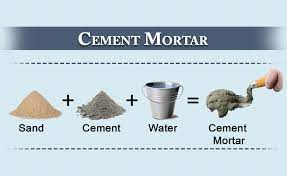

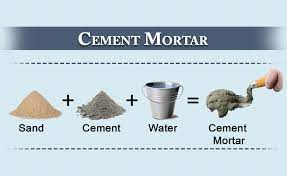

Mortar is a building material that is commonly used to bind bricks, blocks, and other masonry units together. It is a mixture of sand, cement, and water. It is widely used in all types of construction projects.

Each component used in the mortar mixture plays an important role in its performance, strength, and durability. But sand, which seems like a minor element, plays a crucial role in the effectiveness of mortar.

The functions of sand in mortar are numerous and varied, from improving the workability of the mixture to improving its adhesion and compressive strength. The type and quality of sand used significantly affect the quality of mortar.

So, it is important to carefully select and use the appropriate sand for each application. In this article, we will explore the functions of sand in mortar in detail.

Functions of Sand in Mortar

1. Filling Voids

One of the most important functions of sand in mortar is to fill the gaps between bricks or block units. When bricks are laid, there are gaps between them that need to be filled to create a strong bond.

The sand acts as a small ball bearing here. It allows the units to settle into place while maintaining a strong bond. The size and shape of sand particles also have a significant impact on their ability to fill voids.

If the sand particles are too large or irregular, they may not be able to fill the gaps properly. On the other hand, if the particles are too small, they may not provide enough support to hold the units in place. Thus, the ideal size of sand particles for mortar is between 0.15mm to 5mm.

This size range allows the sand particles to fill the gaps effectively and create a strong bond between the components.

2. Strength and Durability

Another critical function of sand in mortar is to add strength and durability to the mixture. When sand is combined with cement and water, it creates a dense and stable base. This base can withstand the stresses of weather and time.

The strength of the mortar depends upon the proportion of sand to cement in the mixture. If the ratio is too high, the mortar may be too weak and prone to cracking. If the ratio is too low, the mixture may be too stiff and difficult to work with.

In addition to adding strength, it also helps to improve the durability of mortar. When properly mixed and applied, mortar can last for decades or even centuries. However, if the mixture is not properly proportioned or if the sand is of poor quality, the mortar may deteriorate over time.

The ideal ratio of sand to cement in mortar is generally between 2.5:1 and 3:1. This ratio ensures that the mixture is strong and durable and also easy to work with.

3. Workability

The workability of mortar refers to its ability to be spread and applied to masonry units. Sand plays an important role here as it improves workability by providing the right texture and consistency.

The size and shape of sand particles also affect the workability of mortar. If the sand particles are too large, the mixture might become too dry and difficult to work with. If the particles are too small, the mixture might be too wet and weak.

In addition to the size and shape of particles, the amount of sand also plays a crucial role. If too much sand is used, the mixture will become stiff and difficult to spread. If there is very little sand, the mixture will be too runny and prone to cracking or shrinking.

To achieve the ideal workability, the sand should be well-graded and have a range of particle sizes. This ensures that the mixture has the right texture and consistency for easy application.

4. Water Retention

Water is a very important component of mortar. It is needed to activate the cement and create a chemical reaction that hardens the mixture. The sand particles act as a sponge in the mortar mixture.

It absorbs the excess water and prevents it from evaporating too quickly. Sand is also important to regulate the amount of water in the mixture to prevent shrinkage and cracking. It plays an important role in water retention by absorbing and releasing moisture as needed.

This helps prevent the mixture from drying too quickly or unevenly, which leads to defects in the finished product. The amount of water needed in the mixture depends upon the type of sand used and the climatic conditions of the place.

Too much water can make the mixture too weak and prone to cracking. Where too little water can make it stiff and difficult to work with. The type of sand used in the mixture also affects its water retention properties. Fine sand particles have a large surface area as compared to coarse ones.

It means they can absorb more water and create a smoother and more workable texture. In contrast to this, coarse sand particles have a lower surface area and may not retain water effectively. However, they can help to improve the durability of the mixture by,

filling in the gaps and creating a more stable structure.

5. Colour and Texture

While sand is primarily known for its structural and functional benefits in mortar, it also plays a significant role in determining the colour and texture of the final product. The colour of the mortar is determined by the colour of the sand used in the mixture.

The type of sand used also determines the texture of the mortar. Texture refers to the smoothness or roughness of the surface. It can impact the overall look and feel of the structure.The texture is also determined by the size and shape of sand particles used in the mixture.

Coarse sand particles create a rough texture, while fine particles create a smooth texture. The ideal sand particle size for creating a smooth and even texture is well-graded and evenly sized.

Thus, to achieve the desired colour and texture in mortar, it is important to choose the right type of sand. Mixing it in proper proportion with cement and water is also crucial. A skilled mason or contractor works with sand and other materials to achieve the desired aesthetic result.

They also ensure that the mortar is structurally sound and functional.

FAQs

- What is the ideal size of sand particles for mortar?

Ans. The ideal size of sand particles for mortar is between 0.15 to 5mm.

2. How is the strength of mortar determined?

Ans. The strength of mortar is determined by the proportion of sand to cement in the mixture.

3. What is the ideal ratio of sand to cement in the mortar mixture?

Ans. The ideal ratio of sand to cement in a mortar mixture is between 2.5:1 and 3:1.

4. How do the size and shape of sand particles affect the workability of mortar?

Ans. If the sand particles are too large, the mixture might become too dry and difficult to work with. If the particles are too small, the mixture might be too wet and weak.

5. How does sand help with water retention in mortar?

Ans. Sand particles absorb the excess water from the mortar and prevent it from evaporating too quickly. Thus, regulating the amount of water in the mixture and preventing shrinkage and cracking.