Introduction

Cement concrete is a popular building material used in construction around the world. It is a versatile, durable, and cost-effective material that is suitable for a wide range of applications, from building foundations and walls to pavements and bridges.

The quality and performance of concrete depend on the ingredients used in its composition. In this article, we will discuss the key components of cement concrete and their importance in producing high-quality and durable concrete structures.

Components of Cement Concrete

1. Cement

Cement is the binding material that holds the aggregates and other ingredients of concrete together.

It is the most critical ingredient in cement concrete,

and its quality directly affects the strength and durability of the finished product.

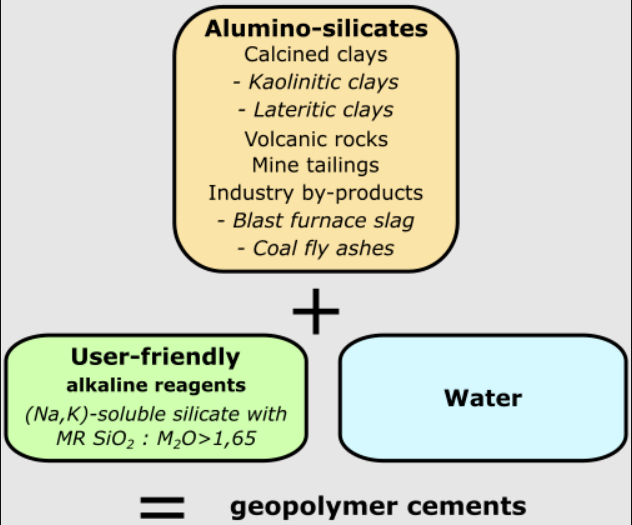

Cement is a finely ground powder made by heating limestone, clay, and other materials to high temperatures in a kiln. The resulting product is called clinker, which is then ground into a fine powder to produce cement.

There are different types of cement available in the market, including Portland cement,

which is the most commonly used type of cement in construction. Other types of cement include rapid-hardening cement,

low-heat cement, sulfate-resisting cement, and white cement. The type of cement used depends on the specific application and the requirements of the project.

2. Aggregates

Aggregates are inert materials, such as sand, gravel, crushed stone, and recycled concrete,

that are mixed with cement to create concrete. They make up the bulk of the concrete mixture and provide volume, stability,

and strength to the finished product. Aggregates can be categorized into two types: coarse aggregates and fine aggregates.

Coarse aggregates are larger particles, such as gravel or crushed stone,

that are typically used in the base layer of concrete. They provide strength and stability to the finished product and help to prevent cracking and settling.

Fine aggregates, such as sand, are smaller particles that are used in the top layer of concrete. They provide a smooth finish to the surface of the concrete and improve its workability.

3. Water

Water is the key ingredient that activates the cement and allows it to bind with the aggregates to form concrete. The quality and amount of water used in the mix are critical to the strength and durability of the finished product.

Too little water can result in a dry and weak mix, while too much water can result in a brittle and porous mix that is prone to cracking and shrinkage.

The amount of water used in the mix is typically expressed as the water-cement ratio (W/C ratio). The lower the W/C ratio, the stronger and more durable the concrete. However, a lower W/C ratio also makes,

the concrete is more difficult to work with and may require more time and effort to properly mix and place.

4. Admixtures

Combinations are chemical or mineral additives that are added to the concrete mix to improve its performance in specific ways. Admixtures can be used to improve the workability, strength, durability, and other properties of the finished product.

Some common types of admixtures include:

- Plasticizers: These admixtures improve the workability of the concrete mix and reduce the amount of water needed to achieve the desired consistency.

- Accelerators: These admixtures speed up the setting and hardening of the concrete, making it possible to achieve the required strength in a shorter period.

- Retarders: These admixtures slow down the setting and hardening of the concrete, making it easier to work with and place in hot weather or large structures.

- Air-entraining agents: These admixtures create tiny air bubbles in the concrete, which improve its durability and resistance to freezing and thawing.

- Water-reducing agents: These admixtures reduce the amount of water needed in the concrete mix, resulting in a more robust and memorable finished product.

Importance of using quality ingredients

The quality of the ingredients used in cement concrete has a significant impact on the final product. The use of poor-quality cement or aggregates can lead to concrete that is weak, brittle, and prone to cracking and erosion.

Poor-quality water can contain harmful chemicals or minerals that can negatively affect the setting and hardening of the cement.

Using high-quality ingredients, on the other hand, can improve the strength, durability, and workability of the concrete. High-quality cement is made from raw materials that have been carefully selected and tested to ensure consistency and reliability.

Quality aggregates are free from impurities and have a uniform size and shape that provides strength and stability to the finished product. Following are several key factors that play key role in maintaining the quality of the cement concrete.

1. Water-cement ratio

The water-cement ratio (W/C ratio) is an essential factor in determining the strength and durability of concrete. The W/C ratio is the ratio of the weight of water to the weight of cement used in the mix. The higher the W/C ratio,

the more water is used, and the weaker the concrete will be. A lower W/C ratio produces stronger, more durable concrete, but it may also make the concrete more difficult to work with and place.

It is essential to maintain the appropriate W/C ratio for the specific application and project requirements. A higher W/C ratio may be suitable for projects that require high workability,

suchas decorative concrete or thin-section applications. A lower W/C ratio is recommended for projects that require higher strength and durability, such as bridges or high-rise buildings.

2. Admixtures

Admixtures are additives that are added to the concrete mix to improve its properties or performance. The use of admixtures can improve the workability, durability, strength, and other properties of the concrete.Water-reducing admixtures can reduce the amount of water needed to achieve the desired consistency of the concrete. This can result in a stronger and more durable finished product while also reducing the risk of shrinkage and cracking.

Air-entraining admixtures create tiny air bubbles in the concrete, which improves its durability and resistance to freeze-thaw cycles. This can be important in areas with cold weather conditions.

Retarding admixtures slows down the setting and hardening of the concrete. This can be useful in hot weather conditions or when working with large structures.

Accelerating admixtures speed up the setting and hardening of the concrete. This can be useful in cold weather conditions or when rapid strength gain is required.

Plasticizers can improve the workability of the concrete mix, making it easier to place and finish. This can be important for decorative concrete or other applications where appearance is important.

FAQ

Q1: What are the main ingredients of cement concrete?

Ans: Cement, aggregates (such as sand, gravel, or crushed stone), and water.

Q2: What is the role of cement in cement concrete?

Ans: Cement is the binding agent that holds the aggregates together and provides strength to the concrete.

Q3: What are some types of aggregates used in cement concrete?

Ans: Sand, gravel, and crushed stone are common types of aggregates used in cement concrete.