Aim:

The aim of this experiment is to determine the particle size distribution of a coarse aggregate sample using sieve analysis and calculate its fineness modulus (FM).

Theory:

The particle size distribution of an aggregate is an important factor that affects the properties of concrete.

Sieve analysis is a method that determines the particle size distribution of an aggregate sample by separating it into different sizes.

and fractions using a series of standard sieves with different mesh sizes. The percentage of aggregate retained on each sieve is then determined and plotted on a graph.

FM or Fineness Modulus is a measure of the particle size distribution of an aggregate sample. It is calculated by adding the cumulative percentages of aggregates retained on each sieve and dividing the sum by 100. The FM is an important factor that is used to proportion concrete mixtures.

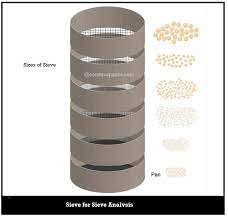

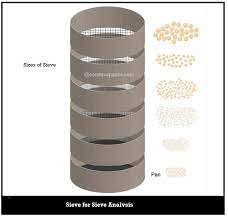

Apparatus and materials required: Sieve Analysis

We require the following set of apparatus and materials to perform the sieve analysis and obtain the FM of coarse aggregates.

- Standard sieves with different mesh sizes (such as 1.18mm, 2.36mm, 4.75mm, 10mm, 12.5mm, 16mm, and 20mm)

- Mechanical shaker or hand sieve

- Balance or scale with an accuracy of 0.1g or better.

- Clean a tray or container to hold the aggregate sample.

- Water

- Oven or drying oven

Procedure: of Sieve Analysis

- Obtain a representative sample of coarse aggregates of about 2 kg in weight.

- Thoroughly wash the coarse aggregate sample to remove any dust particles that may affect the test results.

- Dry the aggregate sample in an oven at about 110 degrees for 24 hours or until it attains a constant weight.

- Now, dry the aggregate sample and record its weight.

- Sieve the aggregate sample through a series of standard sieves arranged in descending order of the mesh size, using a mechanical shaker or a hand sieve. Shake all the sieves for about 10 minutes or until no more material passes through.

- Weigh the aggregate retained on each sieve and record the weight.

- Calculate the percentage of aggregates retained on each sieve and plot it on a graph.

- Calculate the cumulative percentage of aggregates retained on each sieve and plot it on a graph.

- Calculate the fineness modulus (FM) of the aggregate sample using the following formula.

- FM = (cumulative percentage retained) / 100

Data analysis: of Sieve Analysis

You should analyze the data obtained from the experiment using statistical tools such as mean, standard deviation, and error bars. Plotting a graph of the particle size distribution versus sieve size will help visualize the trend of particle size variation.

The data should also be compared with the standard limits for different types of concrete.

Results:

The result of the experiment should include the particle size distribution graph, cumulative percentage graph and the calculated Fineness Modulus (FM) of the coarse aggregate sample. The result should also indicate whether the aggregate sample meets the standard limits for different types of concrete.

Precautions:

- It is important to take care and ensure that the aggregate sample is representative and free from any contamination or unwanted materials.

- Clean and dry the sieves and mechanical shaker or hand sieve before use to avoid any cross-contamination.

- The aggregate sample should be dried in an oven at a constant temperature to avoid any loss of moisture.

- Care should be taken to avoid any errors in weighing or recording the data.

Conclusion:

We successfully conducted an experiment to determine the particle size distribution and Fineness Modulus (FM) of a coarse aggregate sample using sieve analysis.

The result obtained from the experiment provides important information regarding concrete mix design.

Dry the aggregate sample in an oven at a constant temperature to prevent any loss of moisture.

This experiment has also shown that particle size distribution affects the properties of concrete and it is necessary to have a well-graded aggregate to achieve a good concrete mix.

The experiment further demonstrated that the Fineness Modulus (FM) of an aggregate sample can be calculated from the particle size distribution by utilizing the cumulative percentage of aggregate retained on each sieve.

Overall, the experiment has provided valuable insights into the importance of particle size distribution and fineness modulus in the concrete mix design.