Introduction

Steel weight calculation formula is one of the most important concepts in civil engineering. Steel is a major material used in construction for beams, slabs, columns, and footings. Before starting any construction project, civil engineers must calculate the exact quantity of steel required. This helps in cost estimation, material planning, and avoiding wastage. If steel quantity is calculated incorrectly, it may lead to financial loss and structural problems. That is why every civil engineering student, site engineer, and contractor must understand the steel weight calculation formula clearly. In this article, you will learn the formula, examples, and easy methods to calculate steel weight on construction sites.

What is Steel Weight Calculation?

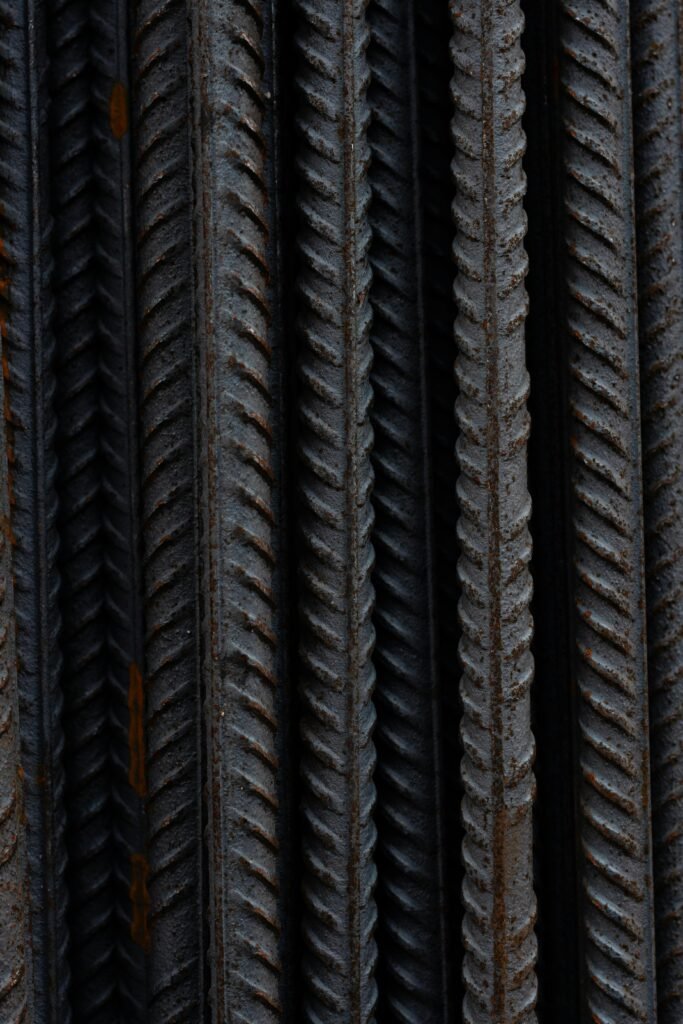

Steel weight calculation is the process of finding the weight of reinforcement bars used in construction. Steel bars are available in different diameters such as 6mm, 8mm, 10mm, 12mm, 16mm, 20mm, and 25mm.

The weight of steel depends on:

- Diameter of steel bar

- Length of steel bar

- Number of bars

By using the standard steel weight calculation formula, engineers can easily find total steel quantity required for construction.

Steel Weight Calculation Formula

The most commonly used steel weight calculation formula in civil engineering is:

Steel Weight (kg) = (D² ÷ 162) × Length

Where:

D = Diameter of steel bar (in mm)

Length = Length of steel bar (in meters)

This formula is used worldwide by civil engineers for accurate steel quantity calculation.

Image source: https://www.pexels.com/

Why 162 Constant is Used?

The constant 162 is derived from the density of steel.

Density of steel = 7850 kg/m³

After calculation and unit conversion, the standard formula becomes:

Weight = D² / 162

This makes calculation simple and fast on site.

Image source: https://www.pexels.com/

Steel Weight Calculation Example

Example 1: 12mm Steel Bar

Length = 10 meters

Diameter = 12mm

Weight = (12 × 12) / 162 × 10

Weight = 144 / 162 × 10

Weight = 0.888 × 10

Weight = 8.88 kg

So, 12mm steel bar of 10m length weighs 8.88 kg.

Example 2: 16mm Steel Bar

Length = 12 meters

Diameter = 16mm

Weight = (16 × 16) / 162 × 12

Weight = 256 / 162 × 12

Weight = 1.58 × 12

Weight = 18.96 kg

This is how steel weight is calculated easily.

Standard Steel Weight Chart

| Diameter | Weight per meter |

|---|---|

| 6mm | 0.222 kg/m |

| 8mm | 0.395 kg/m |

| 10mm | 0.617 kg/m |

| 12mm | 0.888 kg/m |

| 16mm | 1.58 kg/m |

| 20mm | 2.47 kg/m |

| 25mm | 3.85 kg/m |

This table helps civil engineers calculate steel quickly without formula.

Steel Calculation for Slab Example

Suppose a slab requires:

- 10 bars of 12mm

- Length of each bar = 5m

Total length = 10 × 5 = 50m

Weight = (12² / 162) × 50

Weight = 0.888 × 50

Weight = 44.4 kg

This method is used in estimation and bar bending schedule.

Importance of Steel Weight Calculation

Steel weight calculation formula is very important in construction for:

- Accurate estimation

- Cost control

- Avoiding steel wastage

- Material planning

- Billing and tender work

- Structural safety

Every civil engineer must know this formula.

Site Tips for Steel Calculation

Follow these tips at construction site:

- Always check steel diameter

- Measure correct length

- Add extra length for bending

- Use standard formula

- Maintain record in notebook or Excel

Proper calculation saves money and time.

Conclusion

Steel weight calculation formula is essential knowledge for every civil engineer and construction professional. It helps in accurate quantity estimation, cost control, and proper planning of construction materials. By using the simple formula D²/162, you can easily calculate steel weight for any diameter and length.

Understanding steel weight calculation helps in bar bending schedule preparation and project estimation. Every civil engineering student and site engineer should practice this formula regularly for better construction management and accuracy.

Read articles:

1. Concrete Mix Ratio Complete Guide for House Construction

2. Estimation and Costing in Civil Engineering

3) Best Bar Bending Schedule (BBS) Complete Guide for Civil Engineers

4) House Construction Cost in India 2026

5) Quantity-of-cement-sand-and-aggregate-in-1m3-concrete-full-guide